To cope with the low temperatures and snowy conditions of the Arctic, the design includes a number of winterization features. Large sections of the rig are enclosed, including the derrick, working areas, lifeboats, life rafts, mooring windlasses, loading hose stations, ROV launching area, riser storage and pipe rack areas. The helidecks, exposed pipes, exposed door and hatch seals, and escape ways all have heat tracing. Snow covers can be found on escape ways and all exposed stairs and walkways. Insulation or heat tracing would be placed on all water piping that could freeze, while exposed tanks would come equipped with heating coils.

Dalian Developer. It is a logical move for the upstream industry to combine its two largest sectors, drilling and production, which, until recently, have always been kept separate. While the world’s first floating drilling, production, storage and offloading vessel (FDPSO) was put to use in August 2009 by Murphy Oil on Azurite field offshore the Republic of Congo, it was a converted tanker, not a new vessel.

The first actual design created from the ground up as an FDPSO is the MPF 1000 from the now defunct MPF Corp. Cosco Dalian Shipyard is building the first unit based on this design for Dalian Deepwater Development Ltd. at a cost of $500 million. The drillship, named Dalian Developer, is being managed by Vantage Drilling.

With a hull size of 955 ft 3 164 ft, the Dalian Developer is designed to drill in ultra-deep water, up to 10,000 ft, to drilling depths exceeding 30,000 ft. The rig will have a separate production moonpool, and its variable deckload capacity, deck space and cargo storage capacity will be the highest of any drillship ever built. The vessel, with 1 million bbl of crude oil storage capacity, will be upgradeable for enhanced well intervention capabilities, extended well testing and early production.

The hull of the vessel and certain onboard equipment were being built and installed by Cosco Dalian for MPF Corp., which had sought bankruptcy protection in 2008. The contract with Dalian became effective in July 2010, and now the vessel is scheduled for delivery in the third quarter of 2012. When completed, the DP3 rig will be equipped with Maritime Hydraulics-made topdrive, hydraulic roughneck and riser tensioners, and Wirth-made rotary table, mud pumps and drawworks. A six-ram, 15,000-psi Hydril blowout preventer will be paired with two Hydril 10,000-psi annular BOPs. The 180-person unit will also have eight Wartsila engines and thrusters.

Island Innovator. Well intervention is a common procedure, but using typical drilling rings to perform this task has its drawbacks. For one thing, modern rigs have larger BOPs than are generally necessary for well intervention work, which can inadvertently damage older wellheads. Also, rigs are expensive and can make simple well intervention work a costly endeavor.

With that in mind, vessels dedicated to well intervention are becoming a preferred option for many operators, but not many exist today. One unit of this type, the Island Innovator, which is owned by Marine Accurate Well and managed by Island Offshore, is being built to the Global Marine GM4000-WI design.

The rig is under construction at Cosco Zhoushan Shipyard in China and is scheduled for delivery in 2012. The unit can operate as a conventional drilling rig in up to 4,250 ft of water, but can perform through-tubing rotary drilling and heavy well intervention in up to 9,850 ft of water. It can drill to a total depth of 26,250 ft.

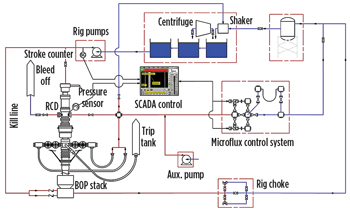

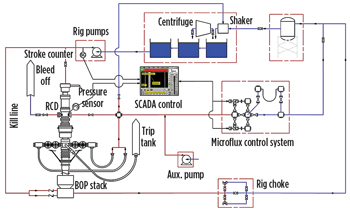

Fig. 2. Weatherford’s closed-loop drilling system.

Fig. 2. Weatherford’s closed-loop drilling system.

The Island Innovator can accommodate four coiled tubing reels with a maximum size of 31/2 in. It is equipped with a 165-ton heave-compensated crane that can work in up to 6,650 ft of water. The harsh environment-capable rig can switch between coiled tubing, wireline and drilling operations in less than an hour.

The DP3 rig is being equipped with a five-ram, 15,000-psi Cameron BOP and VetcoGray risers and diverter. National Oilwell Varco is supplying much of the other equipment on the 120-person rig, including the derrick, main lifting assembly, topdrive, mud pumps and cranes. The unit will be powered by six Wartsila diesel generators.

ALUMINUM DRILL PIPE

While not as complicated as entirely new rig designs, the use of aluminum drill pipe has had a positive impact on offshore drilling operations. While not quite as strong and a little more expensive, aluminum pipes have a big advantage over their traditional steel counterparts: They are considerably lighter. That said, Alcoa’s aluminum alloy drill pipe also happens to have the highest strength-to-weight ratio of any drill pipe.

The lighter weight of the pipe allows offshore rigs to increase their maximum drilling depth capability, both because the drillstring is lighter and because a rig’s capacity to hold pipe will increase by 50–100%.

Traditional equipment that is already installed on rigs can handle these pipes without any modification required. Besides improving the speed and efficiency of horizontal and directional drilling, the enhanced elasticity and resiliency of aluminum drill pipe can result in lower lateral wall forces while reducing abrasive wear on tool joints and the pipe body. Also, since the strength of aluminum pipe is still high while the entire assembly is lighter, less energy is required for rotation the overpull maragin is improved.

CLOSED-LOOP DRILLING

Originally designed as a way to aid in the efficiency of managed pressure drilling, closed-loop systems are growing increasing popular due to the fact that they can assist in the detection of possible well control situations. Following the Deepwater Horizon disaster, deepwater operators in particular are showing an interest in any technology that can help prevent a similar incident from occurring, especially when the technology can also make drilling operations more efficient.

Managed pressure drilling has been in use for decades, with a rotating control device (RCD) being implemented in 1968 to create the first closed-loop system. However, it wasn’t until 2004 that managed pressure drilling was first put to use offshore on a jackup rig in the US Gulf of Mexico.

Later that same year, managed pressure drilling broke the floating rig barrier off the coast of Malaysia. Four years later, Weatherford’s Microflux system aided in drilling HPHT wells in the Mediterranean Sea offshore Egypt in an area where the five previous wells had failed to reach total depth.

Weatherford’s closed-loop drilling system employs three key pieces of technology: an RCD, a drilling choke manifold and a coriolis flowmeter. Each of these elements can be used separately, and have been in the past, but Weatherford engineers David Pavel and Brian Grayson explained that it works much better when built as a complete system from the beginning, especially when grouped with their Microflux control system, Fig. 2.

As Pavel and Grayson stated in a paper presented with fellow Weatherford engineer Said Boutalbi to the 2011 SPE/IADC Drilling Conference and Exhibition, “Most of the technology that comprises a closed-loop system is common, readily available oilfield rig equipment that has been used for decades. The exception is the proprietary computerization used to integrate the equipment as a single system for monitoring, analyzing and managing wellbore pressure.”

The RCD is situated on top of the BOP, although for deepwater operations it is part of the upper riser, situated below the tension ring. According to Grayson, getting the RCD to be positioned below the tension ring was a “huge” breakthrough, because that step allowed the system to work in rougher seas. To date, Weatherford has performed eight closed-loop drilling operations from floating rigs, and is currently at work on two floating rigs, one offshore Brazil and another in Indonesia. The company is currently working to adapt the RCD to work when attached to the subsea BOP, which Pavel said would make the system even more efficient.

In a closed-loop system, the RCD’s job is to direct drilling fluids, cuttings and hydrocarbons from the drill pipe-casing annulus via a bearing assembly and elastomeric sealing elements, which provide a barrier between the drillstring and the wellhead. Through this assembly, drilling fluids and cuttings are circulated without impacting drilling operations.