簡介:在深水中,在砂巖表面進行防砂是有可能的。目前人們更樂意選擇在砂巖表面防砂,而不是將其作為像水合物、石蠟、水及其它油藏副產品開采出來并進行處理。

Holistic approach improves sand management

A look at the big picture is driving some operators to improve their predictive ability to enhance sand management as a whole.

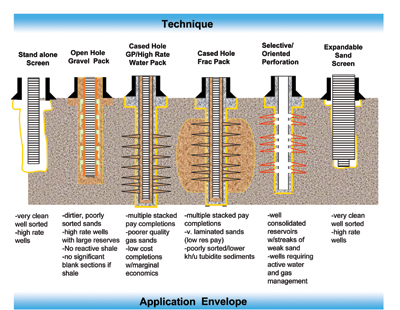

Typical sand control completion options.

Current practices for designing both subsea systems and topsides in deepwater vary between operators but many typically call for zero tolerance for produced sand.

Because some sand production is inevitable for most wells, projects are often carried out with the most advanced sand control applications upfront in the initial completion stage to ensure the well’s success over time.

In deep water, it is possible and has been preferred to control sand at the sand face rather than producing it and managing it as a flow assurance issue as with hydrates, paraffin, or water, and other unwanted byproducts of the reservoir.

Within the last three to four years completion operations have increased both the overall time requirements and cost for deepwater prospects; the industry has experienced a huge spike in cost, with subsalt Gulf of Mexico (GoM) wells often averaging US $1 million/d. For most companies operating in this region, two to three wells drilled and completed in a year is considered a successful program. In the past, most Outer Continental Shelf and onshore wells in the US were completed in approximately 20% of the overall well time. Today, in the deepwater areas of the GoM, completion times often account for 50% or more of the total well time. The resistance against producing any amount of sand combined with the economic risks of getting it wrong often leads operators to eliminate as much risk as possible with complex completion applications.

The industry’s advance into deep reservoirs in deeper waters is leading to renewed efforts to better predict sand production. By developing reliable and accurate tools to predict when and how much sand will be produced, operating companies hope to be able to evaluate every possible alternative for completing deepwater wells.

Sand production

If sand control is not implemented, most wells will produce sand, which might cause several problems if not properly managed, namely erosion and plugging in flowlines and sand accumulation and operational issues in separators and other topsides vessels. Currently, most facilities are not designed to tolerate sand in the flow stream. Tubing, downhole safety valves, and subsea flowlines can be damaged by erosion when exposed to consistent amounts of sand during the production phase. If unchecked, large amounts of sand are capable of plugging flowlines causing shutdowns in production, leading to excessive amounts of non-productive time.

While there are limited ways to manage sand in the flow stream, the inability to predict amounts and size of produced sand and its threat to flow assurance typically limits the selection of management and monitoring programs (which allow some sand production) as viable options.

The reluctance to accept risk is also increased by the high costs of typical intervention operations in deepwater areas. Unlike onshore or shallowwater wells, in subsalt wells (typically 22,000 to 28,000 ft [6,710 to 8.540 m] in 8,000+ ft [2,440+ m] of water), a problem can quickly compound, eroding the prospect’s economics. The need to avoid deepwater and well intervention results in complex solutions being carried out upfront regardless of increased completion times and cost.

A gray area exists where the additional cost of complex completions might not be justified by the characterization of the reservoir indicating any amount of sand production.

The potential benefit to the industry of improving predictive measures for sand production is to ensure that all possible options are weighed in this gray area rather than only those that are the most extreme, and that the best sand management option is selected: a “holistic” approach to sand management.

The operator’s predictive capability is the key enabling component for this holistic approach and needs to be able to answer three questions:

• When will sand be produced?

• How much sand will be produced?

• What are the characteristics of the sand being produced?

Predicting that a reservoir will produce sand at some point in a well’s life is relatively easy with today’s tools. Analyzing core samples in a laboratory can provide great detail on the composition of the rock. Working to delineate the elements of sand production as outlined above requires much more effort. Technology is still needed, but if a holistic approach can be developed, operators can enter into deepwater projects with more confidence in the outcome knowing that all possible options were considered during the process.

Elements of a holistic approach

Overall trends for drilling wells today involve deep water with deeper reservoirs, reservoirs that are hotter with higher pressures and often contain multiple layers of sand. These types of wells require high rates of production to justify the overall expense. More and more new discoveries are becoming smaller (200 to 300 million bbl). To improve the economics for these wells, a reliable predictive tool and a holistic approach to sand management is necessary to aid in selecting the best method of designing each well and the entire production system.

Frac packs are typically the best method to guard against problems arising from produced sand. These types of completions are complex and costly. However, due to the economic risk involved, less robust methods of completions (gravel packs, single screens, and expandable screens) are often overlooked. By improving predictive tools for sand production, operators can make sure that wells are not being over-designed.

From the outset, current reservoir characterization methods can determine that sand production will occur. This could develop as early as two days into production or as late as five to 10 years. By focusing on improving predictive methods, such as using geomechanical algorithms, it may one day be possible to determine when a reservoir will begin to produce sand.

Eliminating some of the 50% completion time in the initial phase of the well could provide more opportunities to drill. The idea of a holistic approach is to understand exactly what is needed ? the complex completion could be postponed for a period of years if a correct prediction were made.

The holistic approach is designed not solely for drilling and completion operations, but also for production, facilities design, and subsea developments. The ability to predict when sand will be produced could also open opportunities to develop tools with increased tolerance to successfully manage some sand production.

Modern techniques for studying rock mechanics help a great deal in understanding the onset of sand production, but they don’t give an indication of how much sand will be produced. Improved monitoring systems could help alleviate this obstacle.

Standard devices use invasive sensors that erode in the presence of sand. Non-invasive monitoring systems may help operators understand the level of sand being produced. Whether the system is designed to be passive or active, the information provided regarding how much sand is in the flow stream would enable more manageable operations and provide a target to develop minimizing strategies. Current work is also underway to improve chokes that are more resistant to erosion, to develop pumps with high degrees of tolerance, to improve separator designs, etc.

Prediction models are made in various stages of reservoir depletion. These are transitioned into full-field multiphase behavior models with sand removal and transport methodologies in place. One gap area in defining improved predictive techniques is the lack of historically matched scenarios. The resistance to sand production and the elements of zero-tolerance designs have encouraged most operators to apply complex methods in the initial phases of development wells.

So far, laboratory models have proven successful. However, there is still a need to match these outcomes in the field.

Once some confidence is built in predictions of volume and characteristics of sand, operators will be better prepared to design for sand production and to better manage the risks involved. An improved approach to modeling sand production could enhance reliability for all methods of completing deepwater wells. Smaller accumulations could better meet their economics, and fields could be produced with greater confidence.