簡介:隨著未來超深水在海上采油中的采油量所占比例越來越大,世界上的油氣供應商不斷開發新技術,以使超深水采油更加經濟,風險更低。

With an increasing percentage of future subsea production expected to occur in ultra-deep water, suppliers to the world’s oil and gas operators continue to push development of technology to make ultra-deepwater production more economic with less risk.

In May, 2005, two members of the Atwater Valley Producers Group (Anadarko Petroleum and Dominion Oil and Gas) awarded a US $110 million contract for umbilical design and manufacture for the Independence project in the Gulf of Mexico (GoM). A year later, Hydro Gulf of Mexico LLC ? also a member of the Atwater group ? awarded a contract for the design and manufacture of its deepwater umbilicals for the same project. For the first time ever, the new technologies of stainless-steel tubes and carbon-fiber rods were combined in an umbilical design.

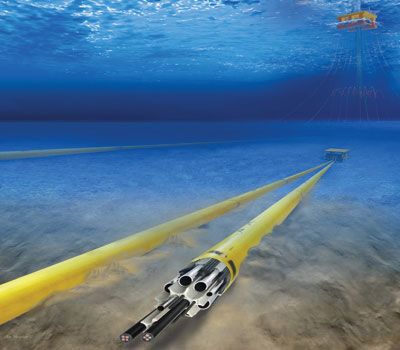

All 15 umbilicals tie back from gas production wells to the Independence Hub, a deep-draft semisubmersible platform installed in 8,000 ft (2,500 m) of water in Mississippi Canyon Block 920, approximately 123 miles (193 km) southeast of Biloxi, Miss. At full production, Independence Hub can deliver 1 bcf/d of natural gas, which represents approximately 12% of the total volume of gas produced from the GoM.

The Independence project consists of three main components: the hub, a massive $385 million platform with a two-level stainless steel production deck; a 24-in. diameter, 134-mile (216 km) pipeline that transports gas processed on the hub to an interconnect with a Tennessee Gas Pipeline located in West Delta Block 68; and a subsea component that includes production wellsets, umbilicals, flow lines, connectors, and manifolds for 15 initial wells. The project is operated by Anadarko Petroleum Co. and owned by Enterprise Products Partners LP and the Atwater Valley Producers Group, a consortium of independent operators.

In 2004, project owners determined that by sharing the $2 billion cost of design, manufacture, installation, and operation of the hub and pipeline, they could make production of natural gas from reservoirs previously deemed uneconomic a winning proposition. First gas flowed to the platform on July 19, 2007.

The subsea component

Umbilicals connect subsea wells from 10 anchor gas fields ? San Jacinto, Spiderman, Q, Merganser, Mondo NW, Atlas NW, Atlas, Vortex, Jubilee, and Cheyenne ? to the hub. The Cheyenne gas field contains the world’s deepest subsea production tree, which lies in 10,233 ft (3,198 m) of water. Other production trees lie in water depths ranging from 7,900 to 8,800 ft (2,469 to 2,750 m). To reach these depths, umbilical design for this project had to resolve issues exacerbated by water temperature, pressure, and depth.

Leo Caffrey, technical manager at Aker Solutions’ umbilical manufacturing facility in Mobile, Ala., explained the design approach. “We use carbon-fiber rods in umbilicals deployed at 7,580 ft (2,453 m) or more of water to provide greater axial stiffness to keep the umbilical from experiencing excessive strain (e.g., elongation), which otherwise would cause the steel tubes to yield and damage electrical cables inside the umbilicals during installation and operation. Carbon-fiber rods add significant axial stiffness, but just a fraction of the weight that would be incurred by adding armoring.”

This approach is innovative. “Before carbon-fiber rods, if you made umbilical tubes of thicker steel to give them greater strength, the added weight offsets the added strength,” Caffrey said. “Eventually, you get to a point of diminishing returns.”

Arild Figenschou, senior specialist engineer based in Aker Solutions’ corporate headquarters in Oslo, Norway, envisioned and led research and development that culminated in successful commercial application of carbon-fiber rods and stainless-steel tubes for umbilicals.

“Traditional thinking for umbilical design is to have one system to take the force of the load (a steel umbilical tube) and to have inside it cables bundled together,” Figenschou explained, “but in water depths of 6,400 to 9,600 ft (2,000 to 3,000 m), where greater axial strength is required by the umbilical, carbon-fiber rods are a superior solution because they add stiffness without adding weight.”

Innovative thinking

Aker Solutions has also pioneered the use of PVC in its umbilicals. Instead of bundling the internal components of an umbilical together and then surrounding them with steel tubes of greater diameter, Figenschou and his R&D colleagues put each element in a separate conduit within a smaller-diameter PVC core inside the umbilical tube. In this patented design, the squeeze load an umbilical experiences in ultra-deep water is distributed to all elements equally.

According to Figenschou, these design enhancements mean there is no need for additional armoring because the stainless steel tube acts like an armor system. “In special cases ? like extremely deep water ? there is greater load on the umbilical from its own suspended weight. The umbilical becomes so heavy, steel tubes alone cannot carry the load,” he explained. “Traditionally, steel armoring was added to the exterior of the umbilical. This created major installation problems. Then we discovered that carbon-fiber rods added to components of the umbilical provided all the axial strength needed. The density of carbon-fiber rods is 1.6 compared to the 7.8 of steel.”

The umbilical for Merganser was the first to incorporate carbon-fiber rods. “We knew the Merganser umbilical would lie in about 8,100 ft (2,531 m) of water,” Caffrey said. “Our clients knew this was an ultra-deep location, so they anticipated a new design approach would be required for the umbilicals. They knew traditional design wouldn’t do, but of course they also required that any new design be tested and qualified to ensure a successful project. Subsea production equipment is never cheap, but subsea production in ultra-deep water is a high-dollar, high-risk endeavor. We knew the more risk we could eliminate by building, testing, redesigning, and retesting prototypes, the greater the margin of safety we would build into the final product.”

Under Figenschou’s oversight, Aker Solutions’ umbilical R&D team in Oslo used the Umbilical Stress Analysis Program (USAP), an advanced analysis tool developed jointly by Aker Solutions and the Marine Technical University, to carry out its work.

“USAP can simulate a whole subsea system during operation of a dynamic umbilical,” Figenschou explained. “It calculates the forces of friction in an umbilical, which is important for determining how the design will react to fatigue. USAP also can analyze different temperatures in different tubes within the same umbilical. This is critical because the mechanical characteristics of elements within the umbilical (such as tubes and cables) can change when their temperatures change, affecting their ability to carry loads.”

Another design challenge required Figenschou and his team to determine how to anchor the individual carbon-fiber rods at each end of the umbilical. Whatever anchoring method they developed would have to be tested and qualified before manufacture of umbilicals for the Independence project.

Such analyses are performed only in Oslo, where the majority of the design of the umbilical layout occurred. When final umbilical cross-section design was completed in Norway, Caffrey and his colleagues in Mobile faced the challenge of translating design into an umbilical prototype.

“We made a full-size, sample-length prototype, then cut it into test sections for the qualification tests described in the ISO 13628-5 standard specification for subsea umbilicals,” Caffrey said. “A whole series of qualification tests was conducted by Tension Member Technology (TMT) at its facility in Huntington Beach, Calif. The same tests were performed on the prototype designed and manufactured for each of the umbilicals in our contracts, beginning with Merganser. As is usual, our clients had full-time inspectors witness the production and the tests.”

Qualification tests validate the accuracy of design. In this case, qualification tests included tensile and fatigue tests. “The fatigue test sets up a length of the umbilical prototype in a machine that simulates 100 years of normal wave motion and 100 years of hurricane wave motion,” Caffrey explained. “The crush test determines whether an umbilical containing carbon-fiber rods could be handled by mechanical tensioners and the lay system without failing during installation. Bend tests measured the stiffness properties of the prototype design, which are critical for successful installation.”

Aker Solutions’ umbilical manufacturing facility in Moss, Norway, is equipped to perform identical qualification tests, but the Mobile facility is not. Careful cost analysis determined it was more economic to transport umbilical prototypes to California for qualification tests than to ship them to the Moss plant.

Following successful testing, the first umbilical containing carbon-fiber rods was delivered in March 2007. Delivery for the last Independence project umbilical took place in July 2007. All of the umbilicals manufactured by Aker Solutions were installed successfully and have operated without incident for more than a year.

Pushing the envelope

Surprisingly, another “push the envelope” challenge surfaced almost immediately. In October 2007, Petrobras Americas Inc. (PAI) awarded Aker Solutions a contract for design, manufacture, and qualification of 44 miles (70 km) of high-voltage power cables as well as static and dynamic steel-tube umbilicals for the Cascade-Chinook subsea development in the Walker Ridge area of the GoM approximately 165 miles (260 km) south of the Louisiana coast. Destined to carry nine high-voltage electric cables to power subsea booster pumps at a water depth of 8,800 ft (2,750 m), each of the power umbilicals will be subjected to the same installation and environmental factors as the Independence umbilicals, but with the added challenges of high internal operating temperatures and an inability to withstand as much load.

“When high-voltage cables within the umbilical are operating normally, they generate heat,” Caffrey said. As the temperature inside the umbilical rises, it becomes less stiff. This application does not require any hydraulic fluid, so the PAI power umbilicals will have no hydraulic steel tubes, an element that, if present, would add some axial strength. “Clearly, this is an umbilical that will require the use of carbon-fiber rods in its design,” he said.

Another first-ever challenge for Aker Solutions’ experts in Oslo and Mobile is the connection of PAI umbilicals to their host. PAI will use the first FPSO ever deployed in the GoM as the host for its Cascade-Chinook production wells. The power umbilicals must be designed and qualified to connect to a buoy mounted on the bottom of the FPSO.

This unique connection will allow a rapid disconnect by the FPSO from the umbilical in advance of severe tropical storms or hurricanes. The disconnected umbilical will sink about 225 ft (70 m) below the surface, and the FPSO will move out of the storm’s path. When the storm is over, the FPSO will be able to return, raise the umbilical, reconnect it to the buoy, and resume production.

“When the buoy is released and the connecting end of the umbilical sinks during that operation, the umbilical undergoes compressive load,” Caffrey explained. “One advantage we discovered during further design and testing after completion of the Independence umbilicals is that the stiffness of the carbon-fiber rods renders the umbilical more capable of handling compressive load without being damaged. In umbilicals without carbon-fiber rods, we need to avoid incurring any compressive load. We found that umbilicals containing carbon-fiber rods can withstand a certain amount of compressive load with no damage. This is a real boon for the Cascade-Chinook power umbilicals where ? as a result of the client’s design requirements ? we know we cannot avoid some compressive load.”

Caffrey noted that all of the qualification tests performed on the Independence umbilical prototypes will be reprised on the PAI umbilicals. He expects those tests to require six to nine months for completion. With this project progressing on track, the company will deliver the Cascade-Chinook power umbilicals in mid-2009.