簡介:可擴展式張力腿平臺(ETLP)將在墨西哥灣殼牌的大足油田安裝,該油田由雪佛龍在2006年一月所發現,水深5330英尺(1615米),大約在新奧爾良南362公里,距雪佛龍大溪地油田56公里。

The extended tension leg platform (ETLP) will see its deepest installation to date if it goes to work as anticipated on Shell’s Big Foot field in the Gulf of Mexico (GoM). Big Foot, which was discovered by Chevron in January 2006, lies in 5,330 ft (1,615 m) water depth on Walker Ridge Block 29, roughly 225 miles (362 km) south of New Orleans and 35 miles (56 km) south of Chevron’s producing Tahiti field.

Pushing the limits

The ETLP is not a new design. It was conceived at Han-Padron Associates (HPA) in 1996 and was based on lessons learned from the design of five TLPs for the GoM.

ABB acquired HPA and the ETLP technology in 1998 and filed for a patent two years later, securing the patent in 2002. Since 2005, FloaTEC LLC, a joint venture between Keppel FELS and J. Ray McDermott, has owned the rights to the design.

The ETLP design is being improved to work at greater depths in the GoM. (Images courtesy of FloaTEC)

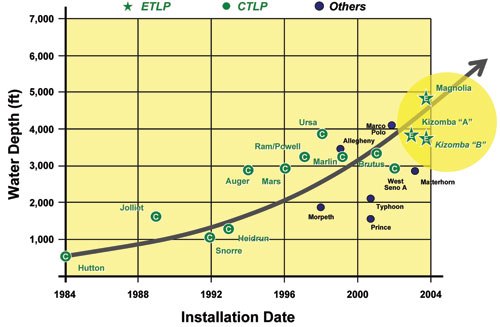

Tension leg platforms (TLPs) historically have been limited to working in around 5,000 ft (1,524 m) water depth because of the challenges associated with tendon design and installation.

The deepest TLP installation to date is Magnolia in Garden Banks blocks 783 and 784 approximately 180 miles (290 km) south of Cameron, La., Conoco developed the field with an ETLP in 2004. The unit is working in 4,700 ft (1,432 m) water depth, and at the time of its installation, displaced the record-holding Marco Polo TLP by 390 ft (120 m).

Though the record-setting installations have been in the GoM, TLPs are not restricted to working there. A number of ETLPs are deployed around the world, including those working for ExxonMobil on the deepwater Kizomba A and Kizomba B projects offshore Angola.

Present plans

Chevron’s objective for Big Foot is to develop the field with a dry-tree floating drilling and production facility.

Technology advancement continues to push TLPs into deeper water.

In early December 2009, the operator awarded front-end engineering work to FloaTEC. FloaTEC is to provide the hull, which will be based on the company’s proprietary ETLP, with associated foundation piles, tendon mooring systems, and top tensioned risers.

FloaTEC will provide engineering and project management services to develop the platform hull design, specify the required marine systems equipment, and optimize the hull, tendons, and risers global design, which includes carrying out the necessary structural analyses. The company also will assist Chevron in estimating the cost of the facility and planning the subsequent phases of the development.

Improving the TLP design

In a move to make the TLP a possible candidate for these deepwater projects, the original designers at Han-Padron identified low-risk configuration changes to the conventional TLP to obtain a highly efficient platform that translate into cost savings. Today, FloaTEC is introducing new design innovations.

Dr. John Murray, director of technology at FloaTEC, said the company is expanding the TLP technology to increase water depth capability. “By doing this, we can offer a wider range of products to the deepwater industry.”

The original patent addressed moving the columns of the platform inboard and extending the pontoons to the tendon porch, which cuts down on the span between the columns while providing the same restoring effects from the tendons as the conventional TLP design. Decoupling the column spacing from tendon spacing reduces the amount of structural steel required for the hull, which in turn reduces the cost.

“This idea takes advantage of a broad base between tendon porches, while reducing the span of the steel supporting the topsides, resulting in a more efficient hull design,” Murray said.

The primary goal was to reduce the weight of the platform, which would also lower the construction cost and the overall platform size. Design changes resulted in more than 40% steel weight savings in the deck and hull while allowing greater payloads to be carried into deeper water. The smaller hull also requires fewer tendons.

Another improvement aims to extend the water depth capability, which would make the ETLP a candidate for fields in water depths that were previously restricted to deepwater floaters such as spars and semisubmersibles.

“In the last three decades, water depth capability has grown by 3,000 ft (915 m) per decade,” Murray said. “We are providing new steel tendon designs that take advantage of experience gained from all deepwater designs. By applying improved engineering methods and materials, engineers have made advances in tendon design that will allow the ETLP to be deployed at greater depths than ever before.”

While these modifications were being made, it was critical to preserve the functionality of the system as well as its constructability. Engineers had to maintain the ability to lift or mate the deck with the hull and to carry out integration and commissioning at quayside or near shore. The compact hull form suits a number of construction methods and options including near-shore or quayside deck/hull integration and commissioning, which reduces offshore installation time, eliminates the need for lengthy transports, and reduces risk.

Design benefits

One advantage of the ETLP is that it has very high structural efficiency, particularly in regions more benign than the GoM.

“The environmental forces on the hull and tendon system are more demanding in the Gulf of Mexico than in most other operating environments in the world,” Murray said. “So in regions such as West Africa, where the environment is more benign, we can further reduce the span between the columns and improve the efficiency of the hull even more.”

Smaller versions of the ETLP offer even greater savings by reducing the number of columns from four to three.

“This design would be an option for wellhead platforms or in cases where there is a requirement for small topsides payload,” Murray explained.

The TLP is one of a few proven floater solutions that can support dry-tree risers. A dry tree completion approach allows a much higher level of reservoir management and productivity. “Part of the reason for this is the ease of intervention with the TLP,” Murray said.

Another advantage of the ETLP is that it does not require deep water at quayside for construction. “These systems can be built in yards all over the world,” Murray said, “and the simplified construction allows a high level of in-country participation.” A further construction benefit is a significant reduction in delivery time. Offshore risk mitigation and cost savings also can be factored into the equation because the ETLP can be fully integrated and commissioned near shore or at quayside. And robustness and safety aspects of the ETLP are equivalent to the conventional TLP.

FloaTEC’s basic design includes full production and drilling capabilities as well as quarters for onboard personnel. The production unit is fully self-contained and is designed to export fluids to a pipeline or floating storage and offloading vessel.

Other opportunities for ETLP technology include those where activity is restricted to drilling (no production), tender-assisted drilling, and in wet-tree production applications.

Ongoing technology development efforts are aimed at further reducing cost, extending the limits of the ETLP’s application, and broadening construction flexibility.